In-Situ Hybrid Layerwise Rolling and Sealing in Additive Manufacturing of Tungsten: Fundamental Processing Mechanisms and Transition Temperature Controls

Refractory metals and alloys of extremely high melting temperatures, particularly tungsten (chemical symbol: W), offer great potential for applications in harsh environments found in the space, defense, and nuclear applications, etc. Additive manufacturing has been explored in the research and development of tungsten parts because of its ability to produce complex single-piece components along with reducing lead times and prototype costs. However, the inherent brittleness and high susceptibility to cracking of this material class pose major challenges to its production using high-temperature additive manufacturing such as laser powder-bed fusion (LPBF). This Faculty Early Career Development (CAREER) grant supports fundamental research that will generate knowledge related to a new hybrid manufacturing technique, combing in-situ rolling and sealing layer-by-layer during LPBF of W parts, capable of performing real-time modifications during the process, and thus, producing parts with controlled and improved properties. The research will enable knowledge-driven processing designs for the advanced production technology of W parts, which would open doors to new applications ranging from waveguides and collimators for hypersonic aircraft leading edges and plasma-facing components in unique fusion reactors, and thereby, create opportunities to strengthen the U.S. economy and national security. This project will also design and deliver intriguing hands-on educational and outreach experiences for the recruitment of diverse high school students to STEM majors and the retainment of undergraduate and graduate students from underserved groups, while ensuring their success in STEM-related careers or post-graduate education. (More details)

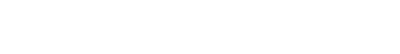

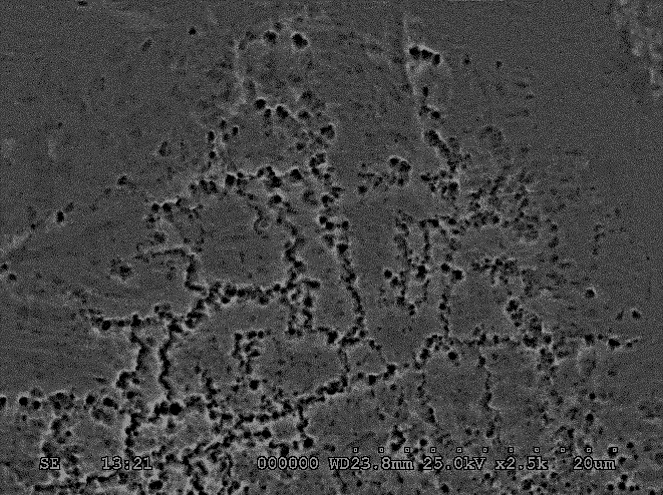

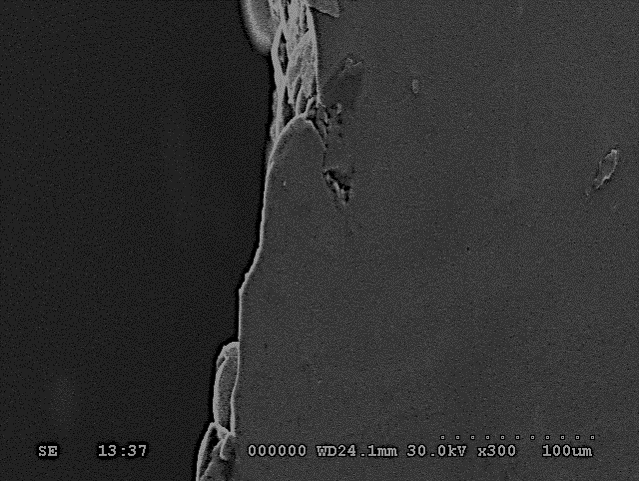

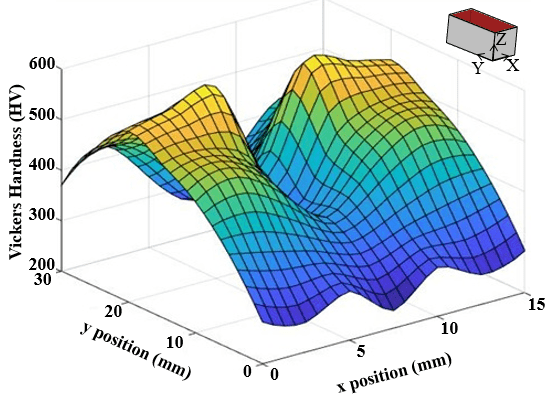

Spatial Variation in Microstructure and Metallurgical Properties of Selective Laser Melted Parts

Parts made by current AM techniques tend to exhibit significant surface defects, including pores, cracks, and un-melted/partially-melted powder particles. Small surface defects coupled with the fact that inelastic deformation occurs more at the surface results in the surface being the source of cracks, which could be very detrimental to fatigue resistance and part strength. To date, no work has been done to understand and control the surface microstructure of AM materials in a way to ensure best mechanical strength and fatigue life in the final components. This research addresses this critical problem and presents a research plan based on a combined fabrication and experimental approach to enable the control over surface microstructure, mechanical strength, and fatigue behavior in AM parts.

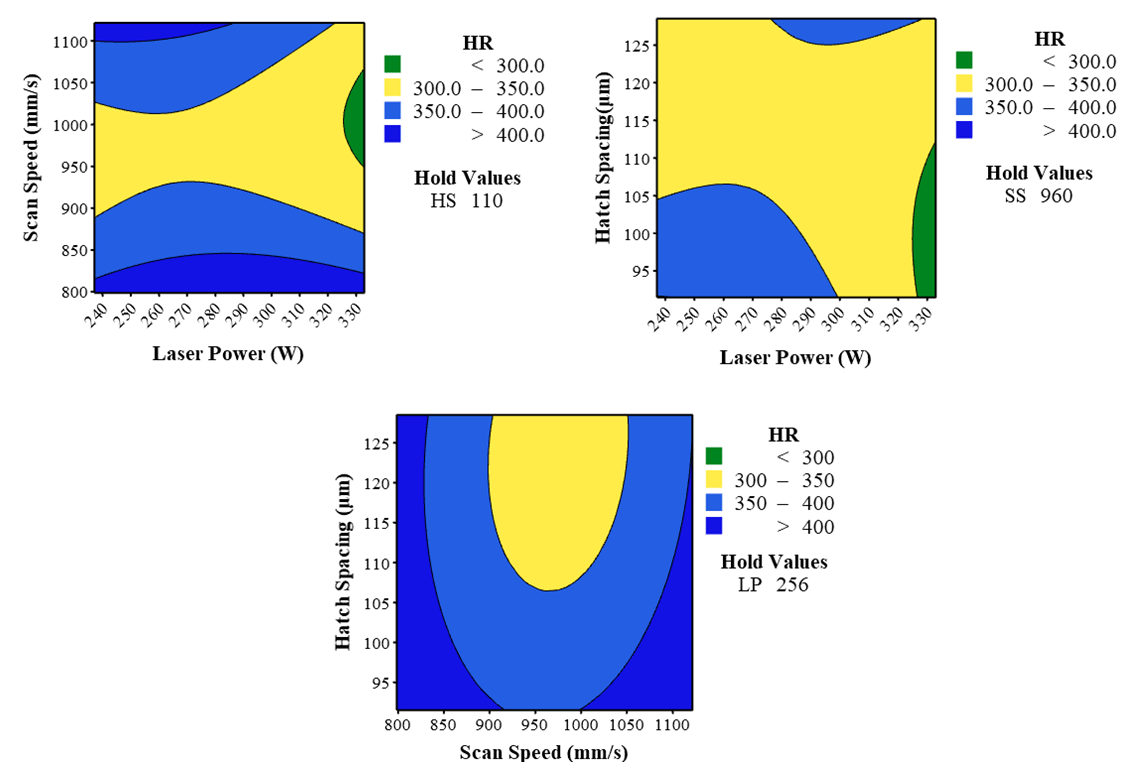

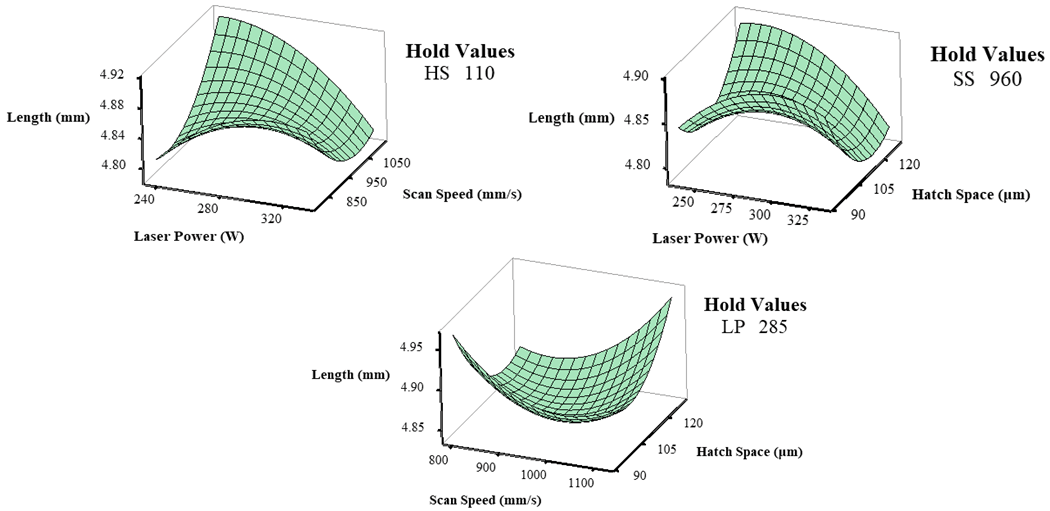

Development of Functional High-Temperature Alloys for Aerospace Applications

Selective laser melting (SLM) is the most common powder-bed additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powder to fabricate functional parts with high accuracy. However, the accuracy and the functional properties of the fabricated parts are greatly dependent on the process parameters. Thus, depending on the desired properties, the process parameters for a given material need to be optimized for improving the overall reliability of the SLM devices. The processing parameters that control the SLM process comprise of the laser power, scan speed, hatch spacing and layer thickness. These process parameters are dependent on each other and therefore making the task of optimizing the process parameters an important one.

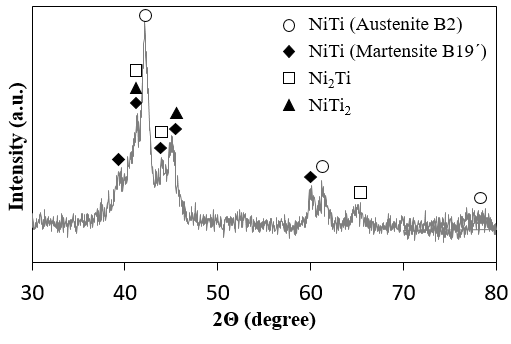

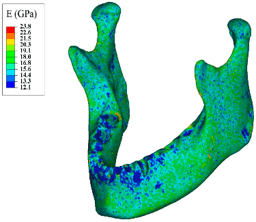

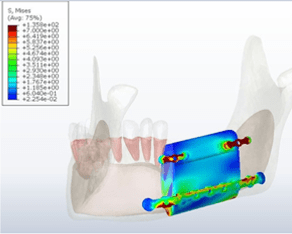

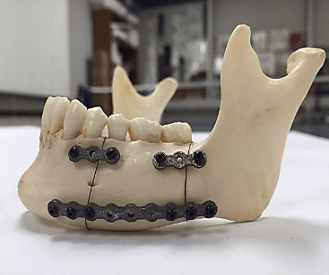

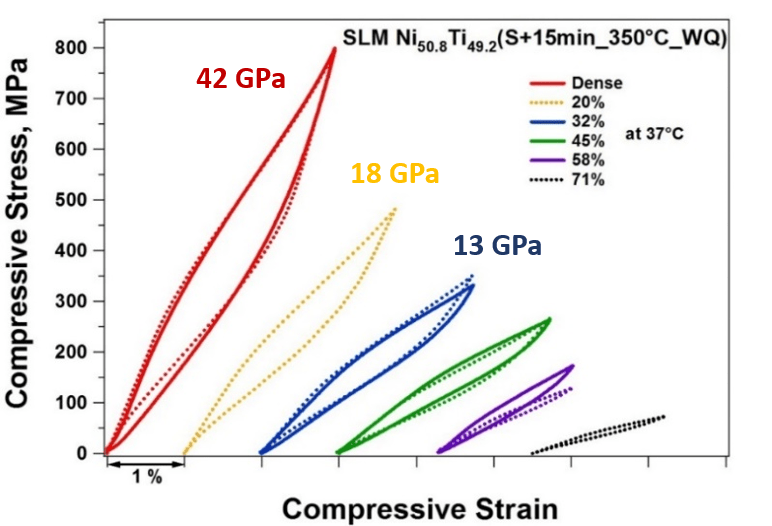

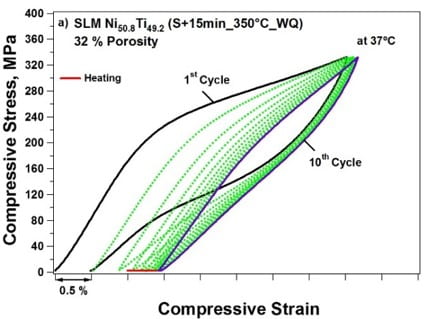

Patient-Specific Porous Nitinol Bone Fixation Plates to Treat Cranial Defects

In this study we investigate porous nitinol (NiTi) as a substitute for Ti-6Al-4V skeletal fixation devices. Porosity can be introduced into the design to reduce, in effect to tune, the stiffness of 3D printed nitinol fixation devices. The tuned, or stiffness-matched, nitinol device must have sufficient stiffness for fixation during a 6-9 month healing period and sufficient flexibility to recreate normal stress distribution once the bone is healed. We compare finite element models of fixation hardware fabricated from Ti-6Al-4V and stiffness-matched nitinol. Our results suggest that stiffness-matched nitinol hardware is more likely to recreate normal stress-strain trajectories in a reconstructed mandibular segmental defect than a Ti-6Al-4V fixation device. This outcome bodes well for surgical reconstruction of skeletal elements in general, and specifically reconstruction of mandibular segmental defects where therapeutic goals include restoration of the chewing, speaking, swallowing, and breathing functions supported by the mandible.